Produce smarter, safer, and without delays

with AI solutions tailored for the food industry

Food Industry

Challenges in the

Food Industry

In food production, consistency, hygiene, and efficiency are mission critical. Yet producers still face ongoing challenges: sudden line stoppages, human errors, costly recalls, and ever-tightening compliance requirements. With increasing pressure on output and safety, staying ahead isn’t optional it’s vital.

Our AI-Powered Solution

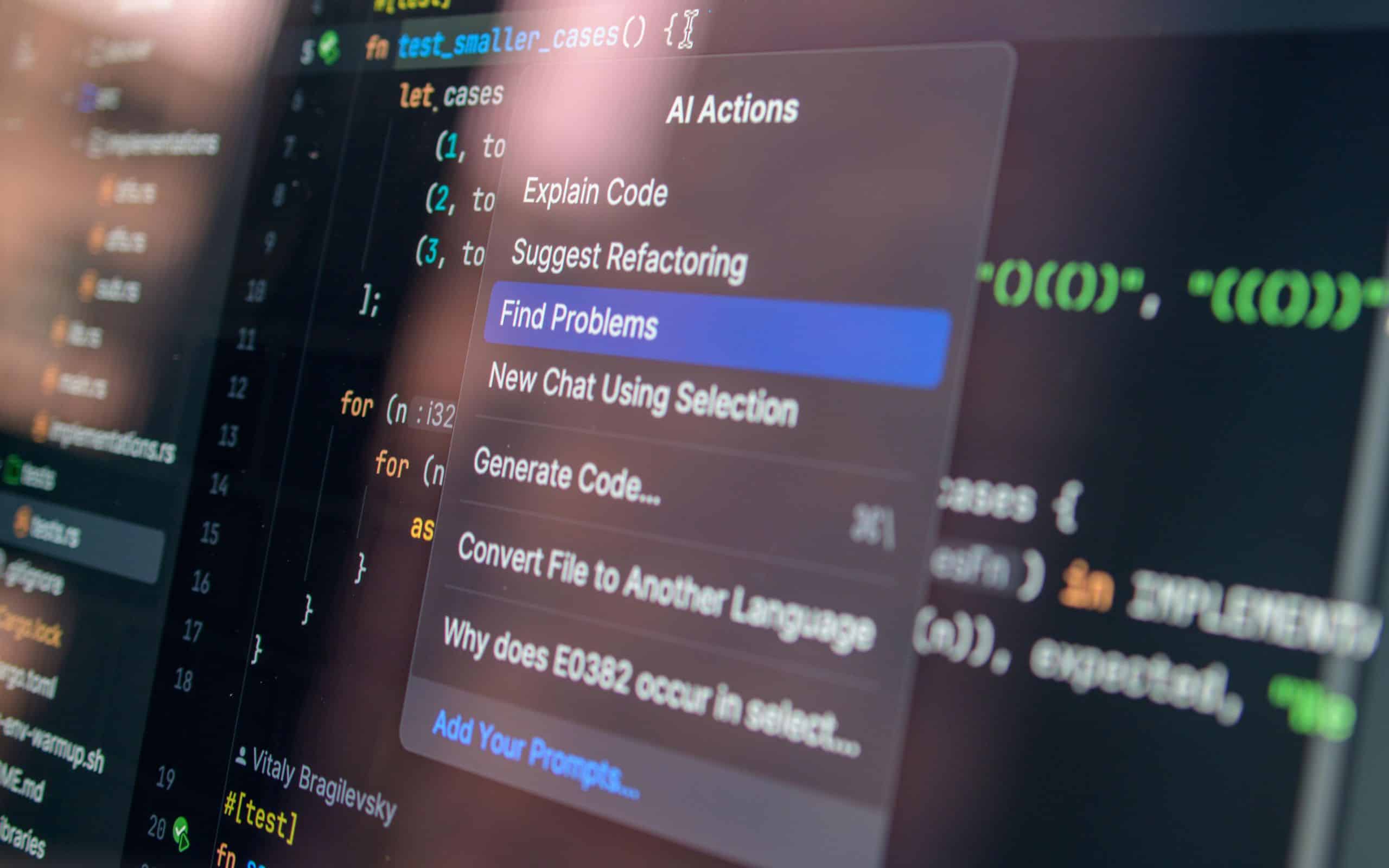

Our AI-powered solutions transform your food production operations into intelligent, self-optimizing systems.

Through cutting-edge digital twin technology, we create a virtual replica of your entire processing line — allowing you to monitor, analyze, and optimize production in real time. That means fewer interruptions, reduced waste, and better control over every batch.

We bring food quality and safety into the AI age:

-

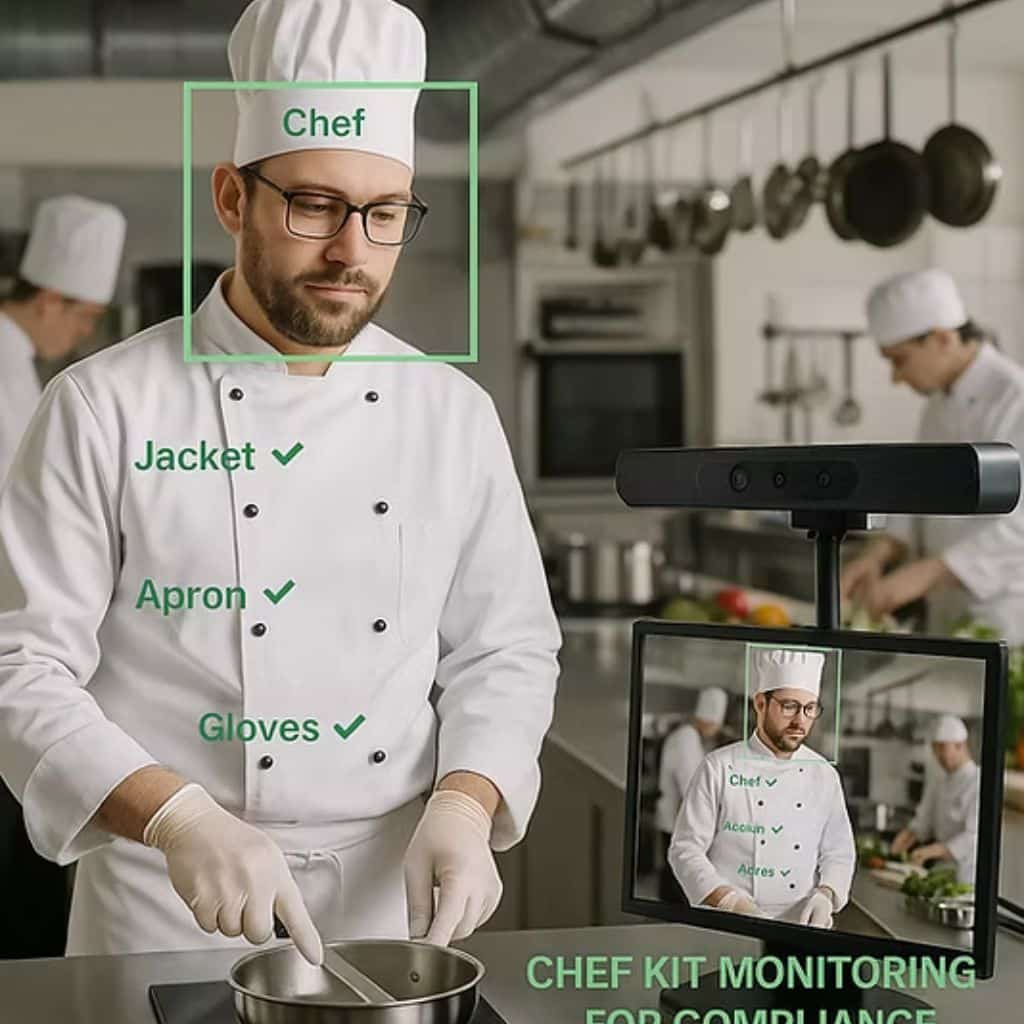

Computer vision inspects products and packaging in real time — detecting imperfections, contamination, or labeling errors before they leave the line.

-

Predictive maintenance prevents unplanned downtimes by identifying wear and failures before they occur.

-

AI ensures full compliance with hygiene protocols by monitoring operator behavior and automating critical safety checks.

Smarter food production starts here.

Our Smart Food Capabilities

Modular, Scalable, and AI-Driven Solutions

for Every Food Production Need

01. Smart Assets

02. Smart Worker

03. Smart Process

04. Smart Quality

Let’s map your opportunities

Get a free Kitchen/Food Management Quickscan and discover how to keep production flowing —

even with fewer skilled workers.

Results we deliver

25+

Years

Of Experience

70%

Increase in

Operational Speed

90%

Client

Satisfaction

Rate

100+

Projects

Completed